Looking for somewhere to get started using 3D printing, laser cutting, and digital fabrication? The world-wide Fab Lab network provides access to digital fabrication tools based on the ideas of open access, DIY, and knowledge sharing.

The Fab Lab initiative was started by MIT’s Center for Bits and Atoms and now boasts affiliated labs in many countries. I first visited Fab Lab Berlin for their "Build your own 3D printer" workshop. Over the course of one weekend I assembled an i3 Berlin 3D printer from a kit, working alongside the kit’s designers and other people interested in building their own printers. Assembling a 3D printer can be a daunting task, but working as a group made it fast and fun - the lab provides access not just to tools but a community of people excited about digital fabrication.

I spoke with Wolf Jeschonnek, founder of Fab Lab Berlin. Wolf spent three months visiting Fab Labs and maker spaces in the United States (he blogged his adventure) before returning to Berlin to start his own Fab Lab.

For someone that’s not familiar, what is a Fab Lab?

The original idea by MIT was an outreach project to show the general public what the Center for Bits and Atoms was doing, which was digital fabrication. And instead of doing an exhibition or a website they put the most important and most commonly used digital fabrication tools that they were using for research into a space and made them accessible to anyone. That’s the whole idea, basically.

[Fab Labs follow a simple charter of rules and generally use a shared core set of machines and software so that projects and experience can be shared between the labs. They also provide free or in-kind access to the lab at least part of the time each week.]

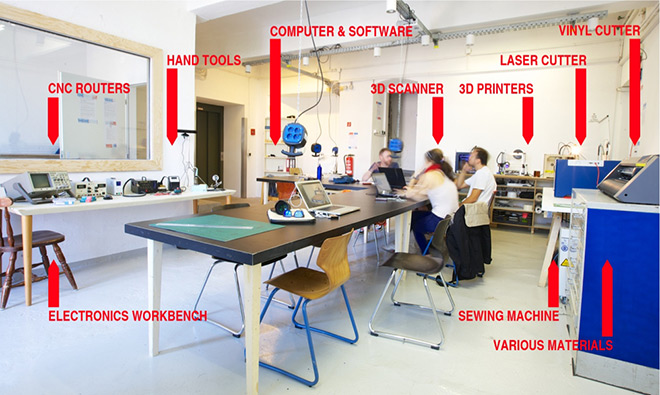

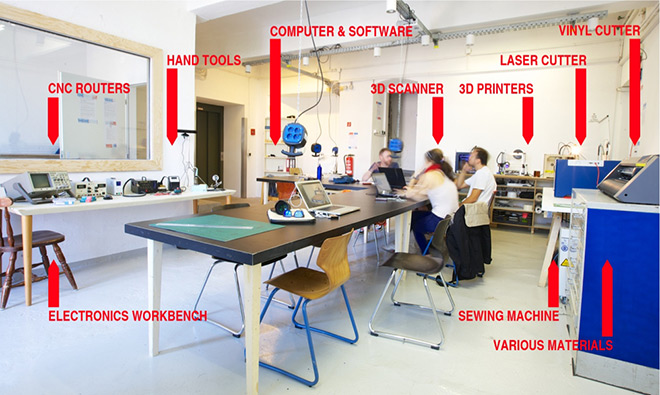

Machines offered at Fab Lab Berlin

You could say the core idea of a Fab Lab is open access to tools for digital fabrication and the sharing of knowledge and experience.

Yes, it’s an open research and development lab, basically. Every university, every art or architecture university has a fab lab. There’s not much difference in the equipment, but it’s not accessible - in most of the universities I experienced it’s not even accessible to the students. They’re very strict about rules and safety and so on. So the innovation is to make those kinds of labs accessible to anyone who’s interested.

It seems like another big difference is that you get hands-on access to the machines. You get to operate the lasercutter - you get to operate the CNC router.

Yes, and also to pass that hands-on knowledge on to the next person who wants to use the lasercutter. In our lab we do a lot of introduction workshops but you can as well just find someone who is willing to show you how the lasercutter works. We have a couple of formal training opportunities for beginners, but after that we don’t do much advanced training, it all happens by people passing their knowledge on to someone else or figuring it out themselves.

In the beginning I was the expert for every machine, because I chose them and knew which machines to buy. By now I’m not the expert at all. If you have a very specific question for technology I’m not the person to ask anymore, because the community is much better.

What are some of your favorite projects that you’ve seen come out of Fab Lab Berlin?

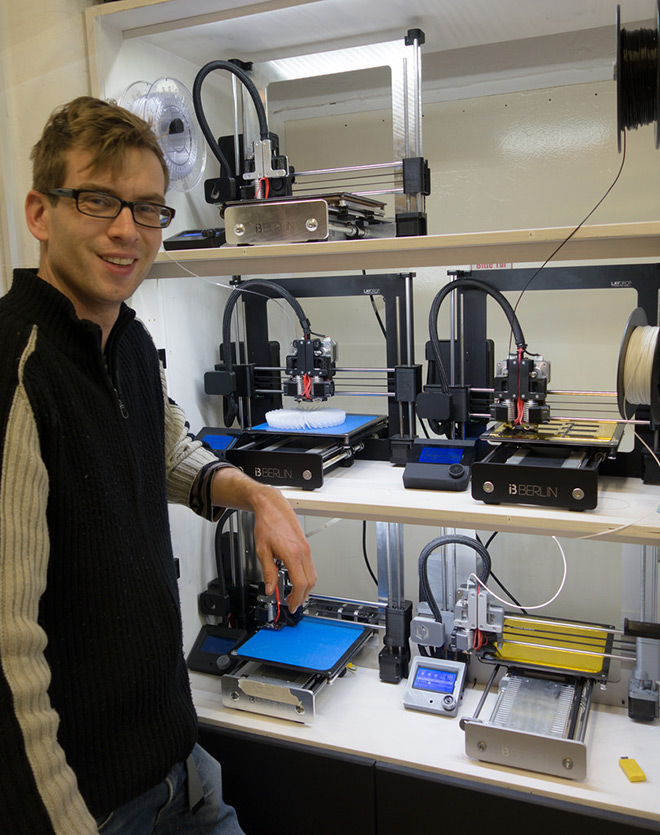

I really like the i3 Berlin 3D printer, because we started together with them, and I could see the development of the machine over the last year and a half. I also built one myself. It was the first machine that we built in the Fab Lab.

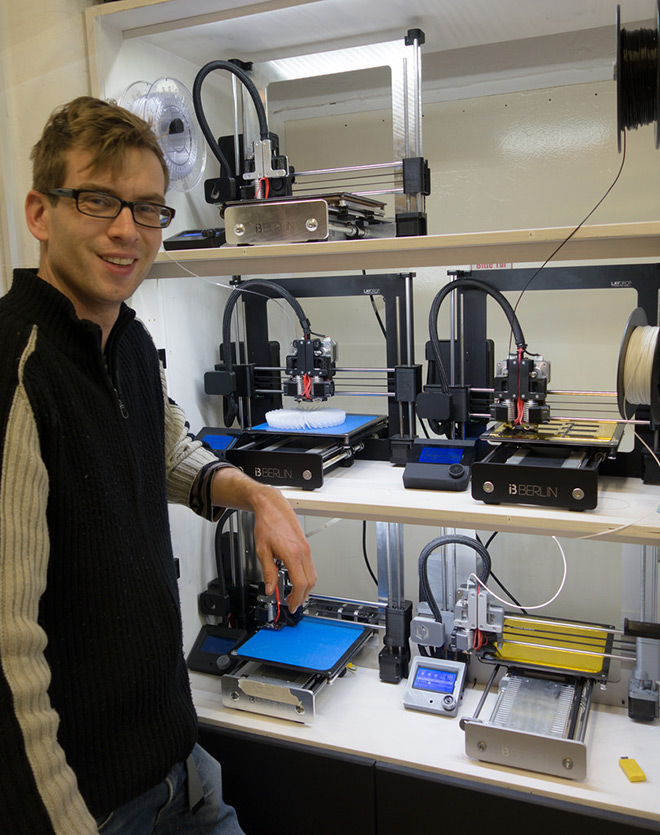

Bram de Vries with several iterations of his i3 Berlin 3D printer

Unlock access to the largest independent learning library in Tech for FREE!

Get unlimited access to 7500+ expert-authored eBooks and video courses covering every tech area you can think of.

Renews at $19.99/month. Cancel anytime

There’s a steadicam rig for a camera that two people built. [The CAMBAL by SeeYa Film.] It’s a very sophisticated motor driven steadicam rig. It’s very steady because the motors have an active control of the movements. Then there is a project that wasn’t really developed in Fab Lab Berlin but it also started with an i3 Berlin workshop. One guy who came and built an i3 Berlin used that printer to design and make a DIY lasercutter. It’s called Mr. Beam. If you look at the machine, the Mr. Beam, you see lots of details that he took from the printer and transferred to the lasercutter. He used the printer that he made himself to build the lasercutter and it was very successful on Kickstarter.

CAMBAL camera stabilizer developed at Fab Lab Berlin. Dig that carbon fibre and milled aluminum!

Do you use open source tools in the Fab Lab? Is there a preference for that?

We try to use as much open source as possible, because we try to enable people to use their own computers to work. It makes a lot of sense to use free software, because obviously you don’t have to pay for it and everybody can install them on their own computers. We try to use open source as much as possible, but sometimes if you do more advanced stuff it makes sense to use something else.

What kind of people do you find using the lab?

That’s very hard to summarize because it’s very broad. There are doctors and lawyers and computer engineers, but also teachers or just people who are interested in how a 3D printer works. The age range is between 6 and 70, I would probably guess. There are some professionals who use the lab and the infrastructure to work on professional projects then there are also people who are very professional in other fields and do very high-level projects, but for a hobby. The reasons why people come to the lab are very different. We also get a lot of interest from large companies and corporations who are interested in how innovation works in an environment like this. It’s been a very good mix of people and companies so far.

Rapid Robots workshop by Niklas Roy / School of Machines, Making & Make-Believe

Do you have any advice for people who are coming to Fab Lab for the first time?

One advice is to bring something to make, because otherwise it’s very boring. It can still be interesting to talk to people, but if you have a project and you already prepared something, you in most cases can find someone who can help you. Then you can make something and it’s a much different experience compared to just watching.

When I toured the United States [visiting Fab Labs] I brought a project - a vertical axis wind turbine. Before I went I really thought hard of a project that I could do. Most people that hang around in a Fab Lab are people who are interested in making stuff. Also talking and sharing knowledge, but the core activity is really making things. If you bring something that’s interesting it’s also a very good starter for conversation.

Thanks, Wolf!

The Fab Foundation maintains a world-wide list of Fab Labs. Fab Lab Berlin has open lab hours each week as well as a number of introductory workshops to get you started with digital fabrication. Most other labs have similar programs. If there isn’t a lab near you, you could be like Wolf and start your own!

About the author:

Michael Ang is a Berlin-based artist and engineer working at the intersection of art, engineering, and the natural world. His latest project is the Polygon Construction Kit, a toolkit for bridging the virtual and physical worlds by translating simple 3D models into physical structures.

United States

United States

Great Britain

Great Britain

India

India

Germany

Germany

France

France

Canada

Canada

Russia

Russia

Spain

Spain

Brazil

Brazil

Australia

Australia

Singapore

Singapore

Canary Islands

Canary Islands

Hungary

Hungary

Ukraine

Ukraine

Luxembourg

Luxembourg

Estonia

Estonia

Lithuania

Lithuania

South Korea

South Korea

Turkey

Turkey

Switzerland

Switzerland

Colombia

Colombia

Taiwan

Taiwan

Chile

Chile

Norway

Norway

Ecuador

Ecuador

Indonesia

Indonesia

New Zealand

New Zealand

Cyprus

Cyprus

Denmark

Denmark

Finland

Finland

Poland

Poland

Malta

Malta

Czechia

Czechia

Austria

Austria

Sweden

Sweden

Italy

Italy

Egypt

Egypt

Belgium

Belgium

Portugal

Portugal

Slovenia

Slovenia

Ireland

Ireland

Romania

Romania

Greece

Greece

Argentina

Argentina

Netherlands

Netherlands

Bulgaria

Bulgaria

Latvia

Latvia

South Africa

South Africa

Malaysia

Malaysia

Japan

Japan

Slovakia

Slovakia

Philippines

Philippines

Mexico

Mexico

Thailand

Thailand